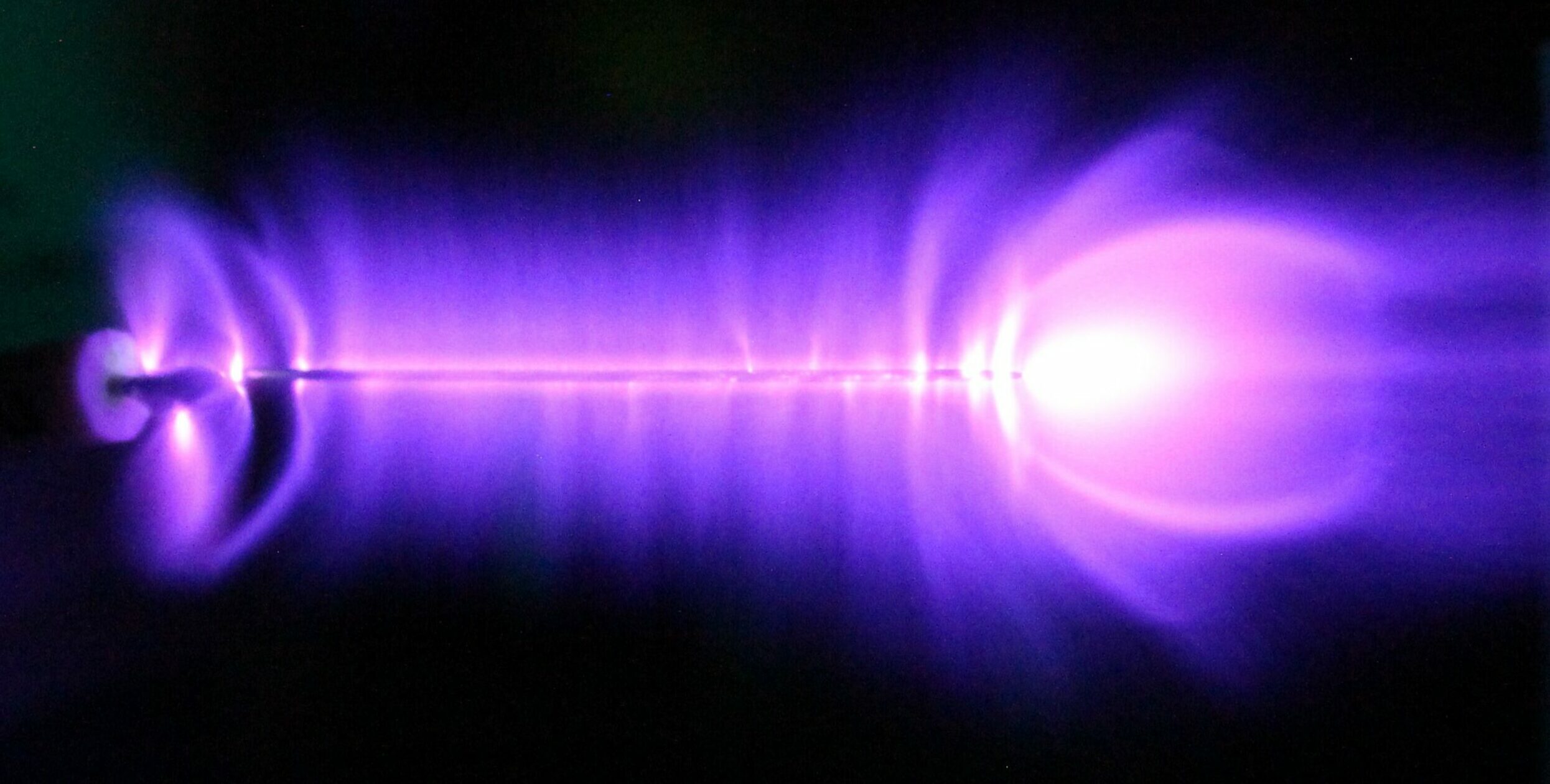

Nanopulsed Plasma

A world-unique patented technology

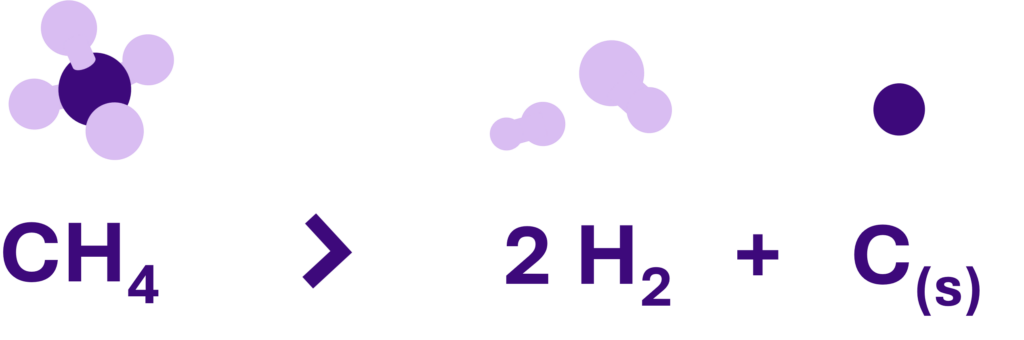

Plasma discharges convert methane into value-added products:

Hydrogen and solid Carbon. The process is known as Methane Plasmalysis.

Methane plasmalysis: Dissolving emissions, Powering progress

Negative with biomethane

Our breakthrough plasmalysis technology splits methane into hydrogen and solid carbon—with zero CO2 emissions. For industries, this means clean hydrogen that seamlessly integrates into existing thermal processes, replacing fossil gas and avoiding 90% of its CO2 emissions that come from combustion. At the same time, we extract and sell high-value solid carbon, eliminating emissions from conventional carbon production.

Sustainable Sparks: a disruptive approach to tackle the need of electrification

than water electrolysis

Our process requires five times less electricity than electrolysis, making it a cost-effective and scalable solution for industrial decarbonization. By operating at controlled temperatures, we maximize energy efficiency while offering an adaptable gas-electricity mix, ideal for regions where renewable electricity is limited but (bio)methane is available.

Hydrogen anywhere, anytime: a modular and plug-and-play technology

No bottom limit

Our plug-and-play units produce hydrogen directly on-site from natural gas, eliminating costly transportation and storage constraints. Each unit can scale to meet demand, producing up to 25 tons of hydrogen per day, while instantly starting and stopping to adapt to industrial needs. The combination of low electricity consumption, on-site production, and carbon valorization makes our hydrogen a cost-competitive alternative to fossil-based industrial heat.